Energy

Introduction

Energy Needs

Solar Energy

Wind Energy

Energy from Wood

−Fuel Value

−Growth Yield

−Planation Size

−Tree Spacing

Heat Engines

Alternators

Batteries

Distribution

Energy for our homes is currently provided by the polluting fuels which profiteering corporations commandeer from our common inheritance to sell back to us in return for our labour. Switching to immediate and sustainable energy will preserve the planet for our children and help win our freedom from corporate slavery. [Português]

We measure energy in joules. It is the same unit for heat energy as for electrical energy as for mechanical energy as for any form of energy. A joule is a watt second. There are 3,600 watt-seconds in a watt-hour, and 3,600,000 watt-seconds (3·6 megajoules) in a kilowatt-hour.

My first task in this personal project is to monitor how much thermal and electrical energy my family actually uses in our suburban home; in other words, to find out our energy needs.

Our domestic energy is currently provided by the national gas and electricity grids from the street. My quest is to see how this energy could be provided directly and sustainably from nature independently of any utility.

Systems like anchored floats to extract energy from ocean waves are not practical for small scale use. Not everybody lives near the ocean. Hydropower — a water wheel or turbine in a fast flowing stream driving an alternator — is also not much use to the majority of people who do not have a mountain stream flowing through their back yards. Electrolytic methods — making damp ground act like a battery cell — give only a very low yield and only work where the ground is damp and acidic. Geothermal energy — natural warmth from below ground — is universally available but involves the cost, practicality and legality of drilling a deep hole in the ground. Small-scale fuel cells are being developed but are currently still way too expensive for household use and would have to be designed for sustainable fuels.

Although wind power is simple and practical, many people find wind fans irritating and unsightly. Consequently, planning permission is difficult to obtain for wind generators of a size capable of providing enough electricity for a household. However, one small wind generator capable of delivering a maximum of about 250 watts can often be erected without planning permission. This may be useful to supplement solar arrays in the depth of winter. There is however another far less obtrusive way of capturing wind energy.

This leaves only the following sustainable sources of energy which are both universal and practical for household use:

There are of course other sources which are currently still at the stage of scientific speculation. These are based on exotic phenomena like

cold fusion

and the

zero-point energy

which is thought to be woven in to the universal fabric of space-time.

Systems which convert these sources of energy into electricity usually also produce heat as a by-product. Since we need heat also, it is well to make use of this heat to warm the house or provide hot water. The process of making use of otherwise wasted heat in the generation of electricity is called co-generation. So far I have considered only the following co-generation systems:

I have also provided an interactive table for calculating the size of backup battery needed to compensate for fluctuations in electrical supply and demand.

My attempt at integrating these into a practical co-generating system is shown below. The little wind generator is an after thought which, it is hoped, will tend to compensate for the reduced performance of the PV array on overcast days and in winter. °

The PV array is water-cooled in winter by a low-temperature home heating system, which is switched to a cooling pond in summer. Keeping it cool makes the PV array more efficient and co-generates heat for keeping the house warm in winter. A low-temperature home heating system provides a more efficient heat sink for the Stirling engine and the PV array. A low temperature central heating system uses much larger radiators operating at only 40 to 45°C. These radiators would normally be implemented as integral sections of wall.

My PV array does not generate quite enough electricity in the depth of winter, yet generates far more than is needed during the summer. This summer excess cannot be stored for winter use. A battery of sufficient size would be way beyond practicality. Nevertheless, this large summer excess of electricity can be put to good use in the cutting of wood for winter. There is also plenty for powering static farm machinery at the time it needs to be used most.

We measure energy in joules. It is the same unit for heat energy as for electrical energy as for mechanical energy as for any form of energy. A joule is a watt second. There are 3,600 watt-seconds in a watt-hour, and 3,600,000 watt-seconds (3·6 megajoules) in a kilowatt-hour.

The following table shows the annual energy consumption for my family's present small suburban detached house. Enter your own values in the kilowatt-hours per year column and then click into one of the other columns. A JavaScript function then calculates and fills in the megajoule and watts figures for later computations.

NOTE: The JavaScript-driven tables in this document pass on the values you enter to subsequent tables so that you can make complete energy calculations for your own situation. Notwithstanding, nothing you enter is stored on your computer. Neither is anything forwarded to my server. Consequently, if you wish to keep your results for future reference, you will have to take a screen shot of each table as you proceed.

We cook by electricity. The heating energy heats the house and provides hot water. The default amount shown also accounts for what is lost to the outside via combustion products — i.e. what goes 'up the chimney', which in our case is a balanced gas flue. I would expect a modern wood burning fireplace to be of comparable efficiency to our 20 year old gas boiler. One should also consider the psychological benefits of the dancing flames of an open log fire over the inanimate facade of a closed stove or boiler on dark winter nights.

This amount of thermal energy provides us with a tolerable, though by no means comfortable, level of heating. With better design and more sensible materials, a house of the same size could be made to provide a very comfortable environment for the same energy consumption.

Annual figures are fine for energy sources which store large amounts of energy in a compact form like wood and rape oil (see oilseed rape crop on the right). However, the availability of solar and wind energy varies considerably with the time of year. For these it is very helpful to know how your demand for heating and electricity varies from month to month during the year.

Annual figures are fine for energy sources which store large amounts of energy in a compact form like wood and rape oil (see oilseed rape crop on the right). However, the availability of solar and wind energy varies considerably with the time of year. For these it is very helpful to know how your demand for heating and electricity varies from month to month during the year.

The following table shows the monthly energy consumption for my family's present small suburban detached house. Enter your own values in the kilowatt-hours per month columns and then click into one of the other columns. A JavaScript function then calculates and fills in the megajoule and watts figures for later computations.

Figures in the above tables are automatically posted to other tables in this HTML file for sizing the various energy conversion systems.

Photovoltaic cells transform light into electricity directly. They use light (not heat) in the range 0·6 to 0·3 microns wavelength. This is the same octave of the electromagnetic spectrum as that used by the human eye. So if the day looks bright, you will know that your photovoltaic array is producing plenty of electricity.

Data on the amount of solar flux in your locality is available from a data source provided by Sandia. The same site also provides data on scaling photovoltaic systems to suit the size of your house.

Photovoltaic cells are not very efficient. The default value in the first field of the following table is the percentage of incident solar energy which is converted to electrical energy by a typical photovoltaic cell. The default value in the lower field is the typical percentage of incident solar energy which can be retrieved from a photovoltaic array via a pumped water cooling system acting as a heat co-generator.

The amount of electrical energy you get from a photovoltaic array is proportional to its active area. Individual photovoltaic cells are often circular. Circles do not tessellate. When you place them in contact with each other on a flat plane, some space is left between them. The total area of your array is therefore always more than its active area. How much more depends on the pattern in which you arrange the circular cells. With the cells arranged in a square pattern, the total array area is 1·273239544735 times its active area. With the cells arranged in a hexagonal pattern, its total area is only 1·102657790844 times its active area. The hexagonal arrangement leaves you with a zigzag edge at each side, but it is the tightest way of packing the cells on a plane.

Change the default value for the active area of your photovoltaic array in the following table. The approximate total array area will then be posted automatically to the lower field. It assumes that the cells are arranged in the more efficient hexagonal pattern.

The default insolation figures si in the following table are adapted from Monthly Maps of Average Daily Solar Radiation from the US National Renewable Energy Laboratories. si is the solar energy in kilowatt hours per square metre per day which is absorbed by a plane collector facing due south and tilted at your latitude + 15° from the north pointing horizontal. This angle maximises its winter yield. The figures are for the extreme north west of Washington State. This is far from where I live but I could not find any data for the United Kingdom.

The electricity and heating demands ed and hd are my own domestic data. The hd figure includes energy for hot water.

se = total incident solar energy on the PV array in Mj per day.

eo = total electrical output of the photovoltaic array in Mj per day.

ep = fraction of ed being provided by the photovoltaic array.

ho = domestic heating from the PV cooling system in Mj per day.

hp = fraction of hd being provided by the array cooling system.

The final 'batt' column gives the number of hours back-up your battery will provide. If you have changed the figures in the Batteries section of this project then your new figures will be the ones used to compute the figures in the 'batt' column of the above table.

Please enter the daily insolation average for each month in the si column for where you live. A JavaScript program then fills in the rest of the table from the si figures you have entered and from the data you have entered in the other tables on this page and other sections of this project.

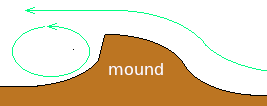

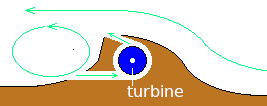

This makes use of the induced eddy that occurs when a prevailing wind, or a sea breeze, blows over a sigmoid shaped hill or mound as illustrated below.

If a flat blade turbine is placed in the eddy, it will rotate. We don't want the turbine to be outside where it would be dangerous or noisy. It can be placed inside the mound as follows, where it would be fully protected and practically inaudible.

The prevailing wind draws air out of the upper vent. This is replaced by air entering through a lower vent in the down-wind side of the mound. This lower vent is fed by the under side of the eddy. The mouth of each vent is covered by a grill.

A pair of standard car alternators could then be attached, one at each end of the turbine shaft. A long enough turbine should provide over 700 watts of steady power while the prevailing wind or sea breeze is blowing. The size of mound you would need in order to implement such a generator is probably a lot smaller than you would think. It could be an artificial mound formed as part of a house roof.

Energy used directly for heating requires no conversion. However, if we derive our electrical energy from a biological fuel like wood, two conversion processes are involved. Each of these loses some of the energy it receives, delivering only a fraction of its input energy in the new form. These fractions are known as conversion efficiencies.

I shall represent these conversion efficiencies as follows:

ke = efficiency of thermo-mechanical process

(eg. in a heat engine)

ka = efficiency of electro-mechanical process

(eg. in an alternator)

Two further 'distribution' efficiencies must be taken into account:

kb = efficiency of electrical storage process

(eg. as in a battery)

we = efficiency of the electrical distribution

(ie. in the wiring)

The energy figures in the top part of the table below are automatically posted from the annual energy table in the Energy Needs section of this project. Adjust the efficiency figures in the middle fields in the table below to suit your own energy conversion efficiencies. A JavaScript program automatically computes and displays the total fuel energy required in the bottom section of the form.

Please email me if you have access to rigorous research figures which disagree significantly with the default efficiency percentages above.

A given amount of fuel, when burned, releases a corresponding amount of heat. The amount of fuel is expressed in terms of mass, which is measured in kilograms. The corresponding amount of energy released is measured in megajoules. The amount of thermal energy released when a kilogram of fuel is burned is called its thermal yield.

Unfortunately, it is not economical or practical to dry fuel wood in an oven before using it. We must let the wood dry at first by natural seasoning and then by being left to stand in stacks after cutting. This leaves some residual moisture in the wood. When we burn the wood, some of the heat produced goes to supply the latent heat of evaporation for this bound moisture. This reduces the useful heat delivered when the wood is burned.

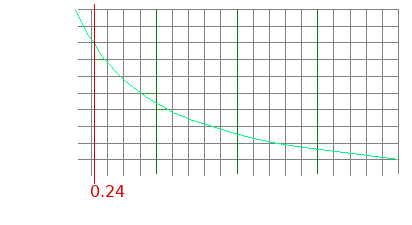

We can reckon dry wood normally to end up with about 24% by weight of bound moisture. To evaporate this takes about 20% of the energy released by combustion.

Data published by the United Nations Food & Agriculture Organisation shows that the thermal energy yield 'ew' of perfectly dry hardwoods is theoretically 19·73 ± 0·98 Mj/kg. However, the energy released by burning a kilogram of wood is a function f(ew, %moisture) of the energy yield of oven-dry wood and its moisture content. This function is plotted in the following graph from the data in Table 5.1.2 on this page at the United Nations Food and Agriculture Organisation website.

We can reckon dry wood normally to end up with about 24% by weight of bound moisture. To evaporate this takes about 20% of the energy released by combustion. Therefore, the useful proportion of the wood's total fuel energy 'kw' is about 0·8.

To get the moisture as low as 24% we need to ring bark the tree in the late spring as soon as it has attained full leaf, then cut it and stack it under cover in the autumn after its leaves have all fallen.

I reckon that to maximise production of fuel wood, trees should be planted, allowed to grow, then cut as soon as their rates of growth start to slow to about 0·707 (the reciprocal of the square root of 2) of their maxima. The problem is finding a non-labour intensive means of measuring individual growth rates.

The yields below, in dry tonnes per hectare per year, were taken from a table published by Oak Ridge National Laboratory in the USA for particular managed plantations. They also list data for some tropical trees.

| Species | High | Average | Location |

|---|---|---|---|

| poplar | 43 | 9-20 | East & Pacific NW US |

| willow | 24 | 13-24 | Northeast US |

| willow | 14 | 8-14 | Sweden |

| willow | 23 | 13-23 | Sweden |

From this I guess that a sensible ball-park expectation for managed tree plantations in temperate latitudes would be about 10 dry tonnes per hectare per year.

The annual yield is had by harvesting trees annually. Enough trees which have past their maximum rate of growth are selected. They are then ring-barked as soon as they have come into full leaf in the Spring. They are then left to 'season' until the Autumn when they are cut, trimmed and stacked. The trimmings and saw dust are then passed through a bacteriological process to reduce them to biomass or wood dust to fire a heat engine.

To produce the wood for our domestic energy needs, we must establish and maintain a plantation which yields a gain of W kilograms of wood per year.

The total energy E is posted automatically to the top field of the following table from the previous form in this document. Adjust the figures in the fields in the middle part of the following table to suit your own findings. A JavaScript program automatically computes and displays the corresponding values for the fields in the bottom part of the table.

Please email me if you have access to rigorous research data which disagrees significantly with the default figures shown above. Note that fast-growing trees need about 3 years to reach their ideal harvesting state. The number of trees required in the plantation is therefore three times the number calculated above. This will comprise three groups of trees planted at intervals of one year apart.

Part of the total wood yield must be in the form of cut logs for burning in a fire or stove. The remainder must be converted to combustible dust for a heat engine. The logs can be cut from a tree's trunk. The engine fuel dust can be made from its branches, twigs and saw dust. These fractions are computed automatically below from the given data.

If wood off-cuts are reduced to dust using a bacterial method, the energy required to do this is minimal and self-acquiring.

The next step is to convert wood off-cuts and dust into electricity. To do this we need a heat engine, an alternator and a back-up battery.

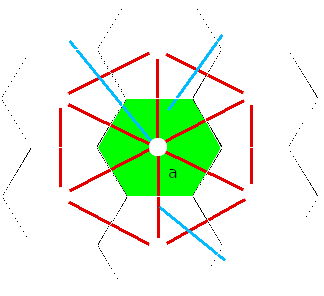

Yield is not all that sensitive to spacing. It should be about 1 to 4 metres depending on whether you want biomass or logs. For the tightest possible packing, trees are planted to form triangles (blue lines in the following diagram).

Each tree can be then considered to have a hexagonal hinterland (green area). This provides each tree with a hinterland closest in shape to a circle, thus providing even space and lighting all round the tree. The perpendicular from the mid point of any of the 6 sides of this hexagonal hinterland to its centre is half the spacing between trees.

Total annual wood yield of a plantation is not very sensitive to spacing. It should be about 1 to 4 metres depending on whether you want biomass or logs. For the ratio of just under 1·3 logs to biomass I need for heating and engine fuel production, I would go for a spacing of 3 metres with a mix of willow, poplar and sycamore and then learn from the results. The mix of tree types is to help in some way towards their biological protection.

A 3 metre spacing makes the area occupied by each tree 0·8660254037844 × 9 = 7·79422863406 m². A plantation of 1 hectare (10,000 m²) therefore requires 10000 / 7·79422863406 = 1283 trees.

I would also try to divide up the plantation into separate areas. This may be a little inconvenient from the point of view of maintenance, but it makes the whole less vulnerable to fire, disease and pests.

There is a large number of different types of device for converting heat into mechanical motion. Many researchers and enthusiasts all over the world experiment with an ever increasing number of different prototypes and kits. I wish I had the means and the time to indulge in this.

As time passes, different technologies have their day. Steam was the first followed by petrol (gasoline) then diesel. A technology which seems to be gaining ground now is the Stirling engine. The claimed efficiencies with which these different types of engine convert fuel energy into mechanical energy for a power range of about 1-10kW are as follows.

| Steam 5% | Petrol 12% | Diesel18% | Stirling 28% |

|---|

Petrol (gasoline) is difficult or even impossible to produce directly on a small distributed scale. A petrol engine cannot be made to run economically on anything we can produce 'down on the farm'.

A small steam engine can be made to be fired by wood or biomass but its maintenance would be safety critical and labour intensive. For instance, an ageing or corroding boiler or a jammed or rusted safety valve could be extremely dangerous.

A popular candidate for small-scale electricity generation is the static bio-diesel engine. Instead of using petroleum based heavy fuel oil, it uses a fuel synthesised from vegetable oil and ethanol. Both these can be made 'down on the farm' from oil rich crops and fermented biomass. With super high pressure 'common rail' injectors delivering precisely controlled staggered fuel spray, coupled with computer controlled engine management, a bio-diesel engine can be quiet, clean and environmentally friendly.

My own personal favourite — at least for the moment — is the linear Stirling engine driving a linear alternator. Its energy source is wood burned, along with any other available biomass, in a hopper fed, fan assisted burner. In hot sunny climates its energy source could be focused solar heat. Its cold sink is maintained by water circulating from a pond or heat exchanger. Heat from its horizontal fan-vented flue can be captured by a heat exchanger for domestic heating and hot water. In a cold climate it may be beneficial to connect a Stirling engine to a wood-burning stove via a thick copper anvil. This would generate domestic electricity all winter while the stove heats the home.

The overall efficiency with which fuel energy is converted to electricity for a commercially produced Stirling powered linear alternator set delivering about 2½kW is claimed to be 22%.

With the exception of the photo-voltaic cell, all the other means, so far discussed, for generating electricity produce mechanical power. This must be converted into electrical power by means of an alternator.

For a bio-diesel, or any other kind of device delivering mechanical power via a rotating shaft, a conventional rotary alternator is required. For my linear Stirling engine, a linear alternator is simply fitted to its reciprocating shaft. In either case, the rating of the alternator must match the power provided by its driving device.

An alternative way of driving an alternator is with wind. Various small wind-driven alternators are available delivering a maximum of about 250 watts. Unfortunately, large wind generators or even lots of small ones, are deemed unsightly by many communities. Nevertheless, one small 250 watt unit can make a worth-while contribution to domestic needs as a supplement to that provided by other means. It is also very simple and hence very reliable. Owing to the great variability of wind, a very sophisticated controller is needed in order to optimise power acquisition under such a wide range of conditions.

Another alternative way of driving an alternator is a mountain stream. Nice if you can get it, but not many people will have one conveniently close to hand.

It is not expedient to rely on an alternator, photovoltaic array or any other direct source to provide a continuous supply of electricity. They are complicated systems. Heat engines can break down. They need to be stopped for maintenance. The sun does not always shine on solar panels. And sometimes the wind does not blow.

The domestic power supply, on the other hand, needs to be constant. The way to bridge this gap is to have a back-up battery to maintain the supply while the primary sources are not producing.

The size of battery required depends on your average power demand and the maximum duration for which your means of generating it is likely to be unable to meet this demand fully. The following interactive table allows you to calculate the amount of backup you need in terms of the familiar car battery. It then computes the size of an equivalent single big battery. The default figures are based on what I would need to provide the current consumption of my suburban house.

The average energy consumption figure has been posted automatically from the annual needs table in the section of this project dealing with energy needs. You can put in your own input figures in the middle part of the table. A JavaScript program calculates the required battery size and shows the results in the bottom part of the table.

My preferred design for a big domestic battery has 6 cylindrical cells of reinforced glass arranged in a circle like the chambers of a revolver and sunk into the ground inside a gravel fill. A central cylinder can then house intelligent inverters to provide various types of electrical supply.

The sheer size of battery required to provide even a day's backup may seem daunting. However, it does not need to be transportable like a car battery. It can be dug into the ground. As a measure of scale, the little study room I am now sitting in is 300cm by 288cm by 232cm high. Its volume is therefore 20044·8 litres. A battery of this volume would provide 400 watts for almost a fortnight. It is a big initial investment, but its large cells are easy to refurbish by the user and should have a life span similar to that of a well built house.

The use of intelligent inverters and a variety of different supply busses will allow simpler more efficient appliances to be used in the home. For example, efficient quartz-halogen or LED (light-emitting diode) lighting would run directly off the battery's 12 volt supply. No transformers necessary, therefore no transformer losses or irritating hum. The intelligent inverters could also provide busses for 15-0-15 and 5-0-5 volt electronics which will be used increasingly, especially for computers and device management systems. This would result in a lower demand for electricity and hence a lower demand for battery capacity.

For critical low consumption devices it is expedient to have small dedicated back-up batteries. For these car or truck batteries can be used.

Being so large, the domestic battery is usually installed outside — either in its own small outbuilding or buried in a large cylindrical hole. The electricity must therefore be somehow conveyed from the battery to the devices requiring it. This is the job of the Distribution System.

Natural energy supplies are intermittent. The sun shines only part of the time. The Stirling engine is only operable when the stove is lit. The wind does not blow every day. Electricity must be stored while it is being generated for use while it is not. This requires a large battery. A battery operating at 115 volts or 240 volts DC (direct current) is too dangerous and impractical. A battery is therefore normally designed to provide electricity at 12 volts and sometimes 24 volts.

For some devices, such as quartz-halogen lighting, the raw 12 volt DC supply is ideal. However, to avoid electrolytic effects such as the corrosion of contacts and the pitting and cratering of switches, it is advisable to reverse the polarity of the supply on a regular basis. This could be done automatically at 2 AM each morning on supplies such as lighting which are not adversely affected by changes in polarity. However, other types of device, especially those containing solid state electronics, cannot tolerate a change in polarity.

For other electrical devices a 12 volt DC supply is neither efficient nor practical. For these, the 12 volt DC supply must be converted to other forms of supply.

Devices containing motors of over 300 watts are much more efficient and cheaper to produce when designed to operate from a 115 or 240 volt supply. To supply such devices, an inverter is required to produce a 115 or 240 volt supply from a 12 volt DC input. The process by which the inverter produces its 115 or 240 volt output causes the electricity to appear first at the higher voltage as AC (alternating current) at 50 to 60 Hertz (cycles per second). Since what are essentially DC motors can almost just as easily use AC, there is no need to rectify it into DC at the higher voltage.

For devices involving complex motor control like automatic washing machines, the controller should be redesigned to operate directly from the original 12 volt supply. However, I prefer the functionality within such controllers to be unbundled. This allows individual sub-units to be replaced independently of the rest of the system as they wear out or become obsolete.

For motors of over 1000 watts, which must provide constant speed at variable torque, a 3-phase 440 volt AC supply is best. These would be in things like large machine tools and static farm machinery. This would require a different kind of inverter.

Devices containing solid-state electronics (such as computers, radio equipment and various types of monitoring and control equipment) require filtered supplies of −12 0 +12 and −5 0 +5 volt DC supplies. Today these devices contain their own internal inverters or power supply units which convert 115 or 240 volts 50 to 60 Herts AC to the kind of supplies the individual device requires internally. However, where, as in our case here, the original supply is at 12 volts DC, it is wasteful first to convert from 12 volts DC to 115 or 240 volts AC and then again to −12 0 +12 and −5 0 +5 volts DC. These internal power units should therefore be replaced with inverters which convert straight from 12 volts DC to −12 0 +12 and −5 0 +5 volts DC. Each should also incorporate a 12 volt backup battery where the supplied device could suffer adversely from a sudden loss of the main supply.

Small low energy discharge lamps are very efficient. They can be made to operate at 12 volts. However, they require it to be supplied as AC at quite a high frequency. I am not sure what the optimum frequency is but I have an idea it is around 500 to 1000 Hertz. If you know about these, please email me. Their supply would require yet another type of inverter and may need to be distributed through coaxial cable.

Where an inverter supplies a single device, switching on the inverter effectively switches on the device. When the device is not in use, the inverter is off. However, where an inverter supplies a distribution bus to which many devices are connected or can be plugged in, the inverter must be on when any one of the devices it supplies is on. To avoid such an inverter having to be on all the time, a common signalling wire (in addition to the power wires) must run between the inverter and the devices it supplies. Through this signal wire, the inverter provides a 12 volt supply from a very high impedance source. Whenever one of the devices it supplies is switched on, that device grounds the signal wire. This tells the inverter to switch on to supply power to the bus. This can be achieved using 3-core cable to supply such devices. One core would supply the power, one would provide the 'power required' signal, the 3rd core being the common return for both. For safety, all 3 wires of the supply bus would not be referenced to ground (earth). There are other ways of doing this without a signal wire, but I think using a separate signal wire is less complicated, less prone to faults and much easier to trouble-shoot.

Finally the question of priority must be addressed. It is vital that certain devices remain running no matter what. Other devices can tolerate irregular interruptions in supply. Vital devices must therefore be supplied with power from what is called an 'essential supply bus'. The others can be supplied from a non-essential supply bus. Below is a sample list of the various types of supply and the types of device each would supply.

Because of the different supply requirements of devices of the same priority, some of the items above may require more than one physical supply bus.

Heat is distributed around the home by pumped water and ducted air. The water-based heating operates by circulating water from the PV array or wood-fired boiler through very large radiators at about 40 to 45°C. These radiators are integral to parts of the walls of the house and are many times the area of conventional central heating radiators. The low operating temperature allows the heating system to act as an efficient heat sink for the PV array.